External Thermal Insulating Composite Systems (ETICS) provide both thermal and weathering protection for exterior walls. Therefore they are not only applied to new buildings but also successfully used for the rehabilitation of old buildings. In the latter case they also provide durable corrosion protection for the reinforcements in prefabricated slab constructions [1]. In all these cases, quick drying-out of the underlying construction is desirable in order to stop corrosion or moisture-induced heat loss. In the following, the drying-out of construction moisture in a 24 cm thick lime silica brick wall with an 80 mm thick ETICS containing mineral wool (MW) or polystyrene foam (EPS) insulation will be investigated by calculation and experiment, and conclusions based on further calculations will be presented.

External Thermal Insulating Composite Systems (ETICS) provide both thermal and weathering protection for exterior walls. Therefore they are not only applied to new buildings but also successfully used for the rehabilitation of old buildings. In the latter case they also provide durable corrosion protection for the reinforcements in prefabricated slab constructions [1]. In all these cases, quick drying-out of the underlying construction is desirable in order to stop corrosion or moisture-induced heat loss. In the following, the drying-out of construction moisture in a 24 cm thick lime silica brick wall with an 80 mm thick ETICS containing mineral wool (MW) or polystyrene foam (EPS) insulation will be investigated by calculation and experiment, and conclusions based on further calculations will be presented.

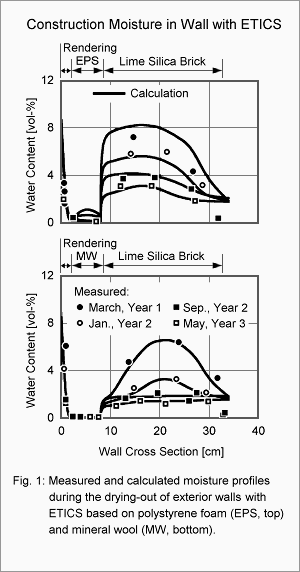

For details on wall construction, material properties and how the outdoor tests and WUFI calculations were performed, please refer to [2]. Fig. 1 shows a comparison of the computed and measured moisture distributions for various points in time after completion of the test house (the measurements were done on drill cores). For both the wall with EPS insulation and the wall with MW insulation good agreement between computed and measured results is achieved.

The shapes of the moisture profiles show that in the wall with EPS insulation most of the moisture is drying toward the interior, while the mineral wool also allows noticeable drying of the masonry toward the exterior. It takes the wall with mineral wool insulation about a year and a half to reach hygroscopic equilibrium, and about twice that time for the EPS insulation. During the drying phase, the heat losses caused by increased thermal transmission and by the increased ventilation necessary for removing the construction moisture are not negligible. In the case of the lime silica brick masonry with its low insulation quality the moisture level during the first year increases the U-value by about 5%. With masonry of aerated honeycomb bricks under the ETICS, the U-value would be increased by about 25%, as shown by computations in [3].

Since the designed U-value is reached only at the end of the drying period, quickly drying wall constructions help to save heating energy. Constructions which are vapor-permeable on both sides and thus can dry equally to the interior and the exterior side are particularly favorable. On the other hand, in walls with vapor-retarding covering on both sides, e.g. with an EPS insulation on the outside and tiles on the inside, it may take the construction moisture more than five years to dry out completely.

Literature

Cziesielski, E.: Energiegerechte Sanierung von Korrosionsschäden bei Stahlbetongebäuden. Bauphysik 13 (1991), H.5, S.138-143.

Künzel, H.M.: Austrocknung von Wandkonstruktionen mit Wärmedämm-Verbundsystemen. Bauphysik 20 (1998), H.1, S.18-23.

Holm, A. und Künzel, H.M.: Trocknung von Mauerwerk mit Wärmedämmverbundsystemen und Einfluß auf den Wärmedurchgang. Tagungsband 10. Bauklimatisches Symposium, Dresden 1999, S.549-558

Page created: 07 May 2007; last update: 17 Jul 2012