Under Central European climate conditions a perimeter insulation usually presents no hygric problems. However, this does not apply to insulation exposed to ground water. In this case only closed-cell insulation materials such as foam glass or extruded polystyrene rigid foam (XPS) are admissible.

Under Central European climate conditions a perimeter insulation usually presents no hygric problems. However, this does not apply to insulation exposed to ground water. In this case only closed-cell insulation materials such as foam glass or extruded polystyrene rigid foam (XPS) are admissible.

Since XPS – as opposed to foam glass – is not completely impermeable to water vapor, care must be taken to prevent water from ever seeping behind the insulation slabs. This can only be ensured by installing the insulation with durable full-face bonding between cellar wall and insulation slabs. Unfortunately, practical experience shows that this is not always done carefully enough and that moisture can then penetrate into areas with no or with incomplete bonding. From the warm side of the insulation slab, vapor diffusion will then transport moisture into the cooler parts of the insulation material. This leads to moisture accumulation in the insulation slabs around these defects and thus degrades the thermal insulation of the cellar.

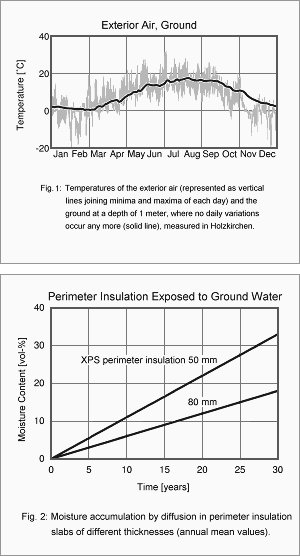

In [1] the moisture behavior of an XPS perimeter insulation applied to walls of a heated cellar has been simulated, assuming that ground water has penetrated behind the insulation slabs. Under the ground temperature conditions shown in Fig. 1 diffusion of the ground water that has seeped behind the warm side of the insulation leads to continuous moisture accumulation in the insulation slabs (Fig. 2).

As opposed to measurements on sporadically taken samples, the simulation allows to extrapolate the moisture conditions over a longer period of time. The long-term moisture accumulation is much more pronounced in a perimeter insulation with only 50 mm thickness than in one with 80 mm thickness. The smaller temperature gradient in the thicker insulation layer gives rise to a smaller vapor pressure gradient on the warm side, which leads to less accumulated moisture because of the reduced vapor diffusion flow. In both cases, in the area around the defect the U-value of the insulated cellar wall increases markedly over the course of 30 years (by about 70% in the 80-mm-insulation and by about 140% in the 50-mm-insulation). Such a degradation of the insulation quality is not acceptable. It is therefore important to exercise great care when applying XPS perimeter insulation slabs exposed to groundwater.

Literature

Künzel, H.M.: Feuchteaufnahme von Perimeterdämmplatten aus extrudiertem Polystyrol-Hartschaum im Grundwasserbereich bei nicht vollflächiger Verklebung. IBP-Bericht FtB-38/1995.

Page created: 27 Apr 2007; last update: 17 Jul 2012