In sandwich wall constructions the outer leaf provides the weathering protection. Even if there is no air gap between the outer leaf and the core insulation, capillary infiltration of rain water is limited to the outer leaf if hydrophobic insulation materials are used and the whole construction is windproof [1]. Thus, if the wall is properly executed, the construction layers behind the facework are durably protected from precipitation water.

In sandwich wall constructions the outer leaf provides the weathering protection. Even if there is no air gap between the outer leaf and the core insulation, capillary infiltration of rain water is limited to the outer leaf if hydrophobic insulation materials are used and the whole construction is windproof [1]. Thus, if the wall is properly executed, the construction layers behind the facework are durably protected from precipitation water.

In summer, however, moisture may be transported into these deeper layers by so-called reverse diffusion (also known as summer condensation). If the outer leaf is heated by sunshine, the rain water it contains will be carried across the core insulation by vapor diffusion and condense in the cooler inner leaf. If the inner leaf is masonry, the condensation moisture is harmlessly absorbed as capillary water in its pore spaces and given off in cooler periods. However, if the inner leaf contains materials which are susceptible to moisture damage, such as wood, summer condensation may create problems.

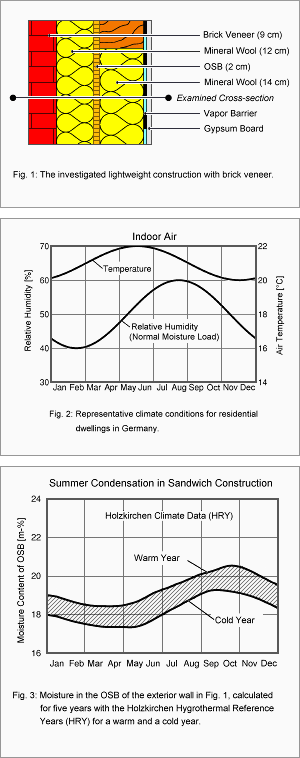

The effect of summer condensation occurring in the wall construction shown in Fig. 1 has been investigated by computational simulation. The inner leaf is a simple wooden post-and-beam structure. The outer leaf is clinker facework with a relatively low water absorption coefficient (A-value) of 1,0 kg/m²h½. The 12-cm-thick cavity between the facework and the OSB board covering the inner leaf is completely filled with hydrophobic mineral wool insulation. The investigation considers a typical cross-section of the west-facing wall during the fifth year of exposure to weather and focuses on the moisture content of the OSB board. The indoor climate used for the calculations is shown in Fig. 2, a cold and a warm year measured in Holzkirchen (HRY – Hygrothermal Reference Years) were used for the outdoor climate conditions.

Fig. 3 shows the spread of moisture conditions that occur in the OSB board, depending on the outdoor climate. In contrast to what is usually expected, the OSB board dries out during winter, starts to continuously accumulate moisture around May, reaches a maximum in autumn and then starts to dry again. As described above, the moisture accumulation during summer is due to reverse vapor diffusion. In a cold year, this does not create a critical situation for the wall construction investigated here. In a warm year, however, the moisture content in the OSB board exceeds 20 mass-%. Since relatively high temperatures occur at the same time, long-term damage caused by microorganisms can not be excluded.

This example is a striking demonstration of the fact that under certain circumstances warm weather can hold a higher risk than colder weather.

Literature

Künzel, H.: Zweischalige Außenwände mit Kerndämmung und Klinkerverblendung. wksb 37 (1996), S. 15-19.

Page created: 08 May 2007; last update: 17 Jul 2012