The drying of a cellular concrete flat roof is a classic example for the application of modern computational simulation methods. Since traditional methods considering only vapor diffusion were not sufficient to explain the drying behavior of these flat roofs, a new calculation method [1] was introduced in the early 80s which allowed for capillary transport, too, and was thus able to quantitatively reproduce experimental results obtained in the 60s [2]. Since this type of construction has recently attracted the attention of experts because of moisture problems during the drying phase in more southern climates, it will be used here as an example for investigating the hygrothermal behaviour of massive flat roofs.

The drying of a cellular concrete flat roof is a classic example for the application of modern computational simulation methods. Since traditional methods considering only vapor diffusion were not sufficient to explain the drying behavior of these flat roofs, a new calculation method [1] was introduced in the early 80s which allowed for capillary transport, too, and was thus able to quantitatively reproduce experimental results obtained in the 60s [2]. Since this type of construction has recently attracted the attention of experts because of moisture problems during the drying phase in more southern climates, it will be used here as an example for investigating the hygrothermal behaviour of massive flat roofs.

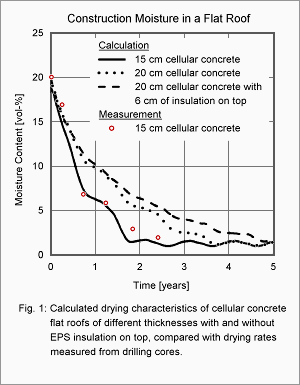

Fig. 1 shows the computed drying curves for three different flat roof variants, each starting with 20 vol-% of construction moisture in the prefabricated cellular concrete elements at the beginning of the first year. A comparison of the computation with measurements obtained for the 15 cm thick roof [2] shows the quality of the calculational prediction. The initial strong drying by 10 vol-% (15 kg/m²) within six months is due to strong heating of the bituminized roof surface by solar irradiation.

Since the roof can only dry towards the indoor side, a strong moisture load on the indoor air is created which must be removed promptly. While at temperate latitudes this is routinely achieved by simply opening the windows for an appropriate period of time, the air conditioning equipment used in hot and humid climate zones often cannot cope with the additional moisture so that indoor humidity may exceed permissible levels during the drying period of the roof.

The designed U-value of the roof is only reached when its moisture content falls below the reference moisture content of cellular concrete (about 1.5 vol-%). With the 15-cm-thick roof this happens within less than two years. A 20 cm thick cellular concrete roof already takes 3.5 years to dry out, which is roughly double the time. If 6 cm of polystyrene insulation are applied on top of the latter roof, its drying time reaches approximately five years. This example demonstrates the considerable influence of solar irradiation on the moisture behavior of flat roofs. While the additional insulation raises the overall temperature level of the cellular concrete, it also strongly suppresses the surface temperature peaks in summer. Since saturation vapor pressure rises exponentially with temperature, this reduction of peak temperatures slows the diffusion-dominated drying following the initial moisture loss which is supported by capillary forces.

Literature

Kießl, K.: Kapillarer und dampfförmiger Feuchtetransport in mehrschichtigen Bauteilen; rechnerische Erfassung und bauphysikalische Anwendung. Diss. Universität-Gesamthochschule Essen 1983.

Künzel, H.: Untersuchungen über die Feuchtigkeitsverhältnisse in Flachdachkonstruktionen. Berichte aus der Bauforschung H. 48, Verlag Ernst & Sohn, Berlin 1966

Page created: 09 May 2007; last update: 17 jul 2012

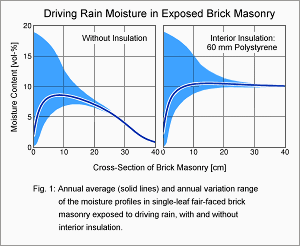

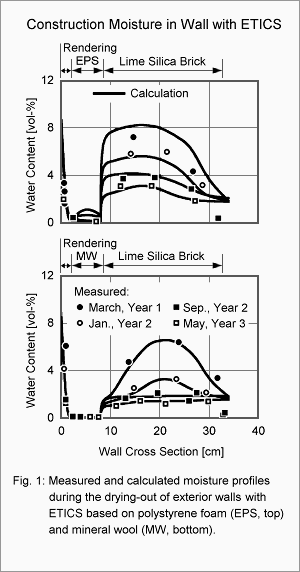

From a hygrothermal point of view, an exterior insulation is in general preferable over an interior insulation. However, economical aspects or the wish to preserve historical facades may rule out exterior insulation, so that interior insulation remains the only way to reduce the energy consumption of a building and to increase comfort. The resulting risk of interstitial condensation and possible countermeasures (e.g. vapor barriers) are widely known.

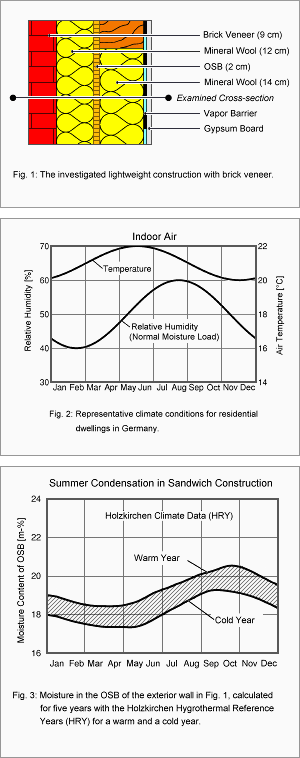

From a hygrothermal point of view, an exterior insulation is in general preferable over an interior insulation. However, economical aspects or the wish to preserve historical facades may rule out exterior insulation, so that interior insulation remains the only way to reduce the energy consumption of a building and to increase comfort. The resulting risk of interstitial condensation and possible countermeasures (e.g. vapor barriers) are widely known. In sandwich wall constructions the outer leaf provides the weathering protection. Even if there is no air gap between the outer leaf and the core insulation, capillary infiltration of rain water is limited to the outer leaf if hydrophobic insulation materials are used and the whole construction is windproof [1]. Thus, if the wall is properly executed, the construction layers behind the facework are durably protected from precipitation water.

In sandwich wall constructions the outer leaf provides the weathering protection. Even if there is no air gap between the outer leaf and the core insulation, capillary infiltration of rain water is limited to the outer leaf if hydrophobic insulation materials are used and the whole construction is windproof [1]. Thus, if the wall is properly executed, the construction layers behind the facework are durably protected from precipitation water.

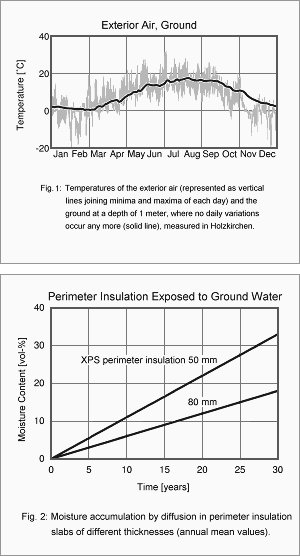

Under Central European climate conditions a perimeter insulation usually presents no hygric problems. However, this does not apply to insulation exposed to ground water. In this case only closed-cell insulation materials such as foam glass or extruded polystyrene rigid foam (XPS) are admissible.

Under Central European climate conditions a perimeter insulation usually presents no hygric problems. However, this does not apply to insulation exposed to ground water. In this case only closed-cell insulation materials such as foam glass or extruded polystyrene rigid foam (XPS) are admissible.